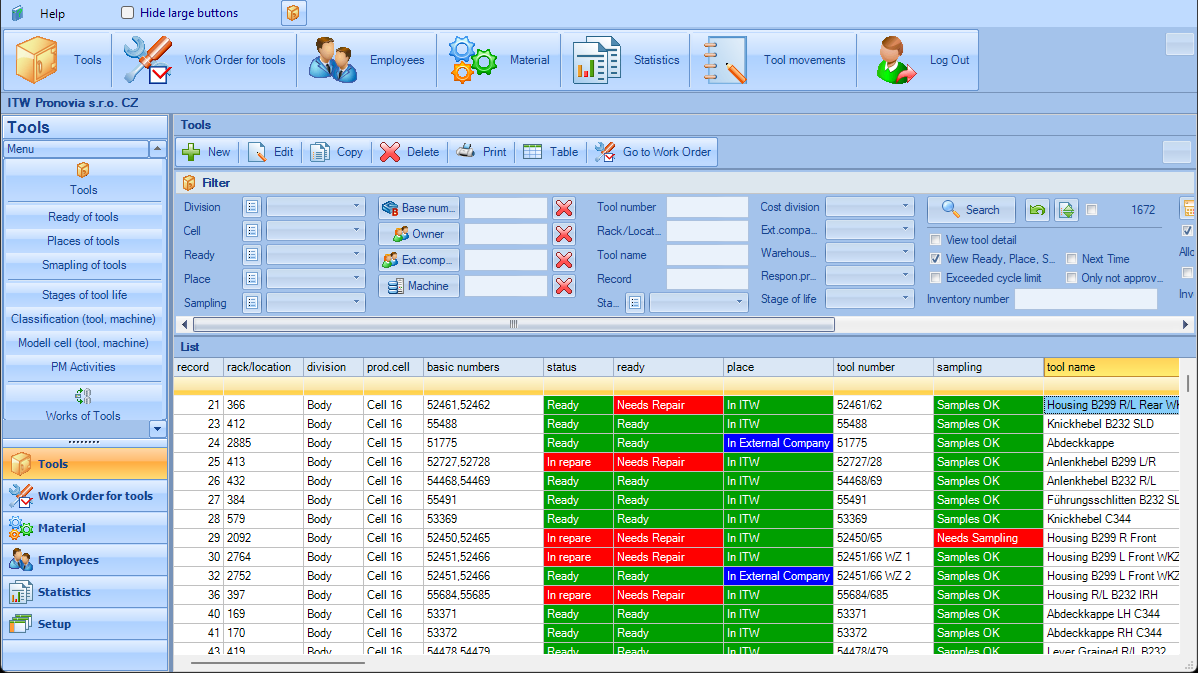

🏷️ Tool Registry & Tracking

Centralized database of production tools with identification, location visibility, and lifecycle tracking. Always know tool status, assignment, and history.

- 🏷️ Unique tool identification

- 📍 Location visibility across facility

- 📊 Usage history and lifecycle statistics

- ⚙️ Assignment to machines or operators

🛠️ Preventive Maintenance Automation

Within the ToolShop module, each tool can have cycle-based maintenance thresholds defined. Production cycle counts are tracked automatically and maintenance tasks are generated when limits are reached — no manual monitoring or calculations required.

- 🔢 Maintenance triggered by real production cycles

- 🔗 Direct data flow from Production module

- ⚙️ Automatic work order generation

- 📢 Timely notification of toolshop personnel

- 📊 Lifetime tracking per tool

- 🗂️ Full service history recording

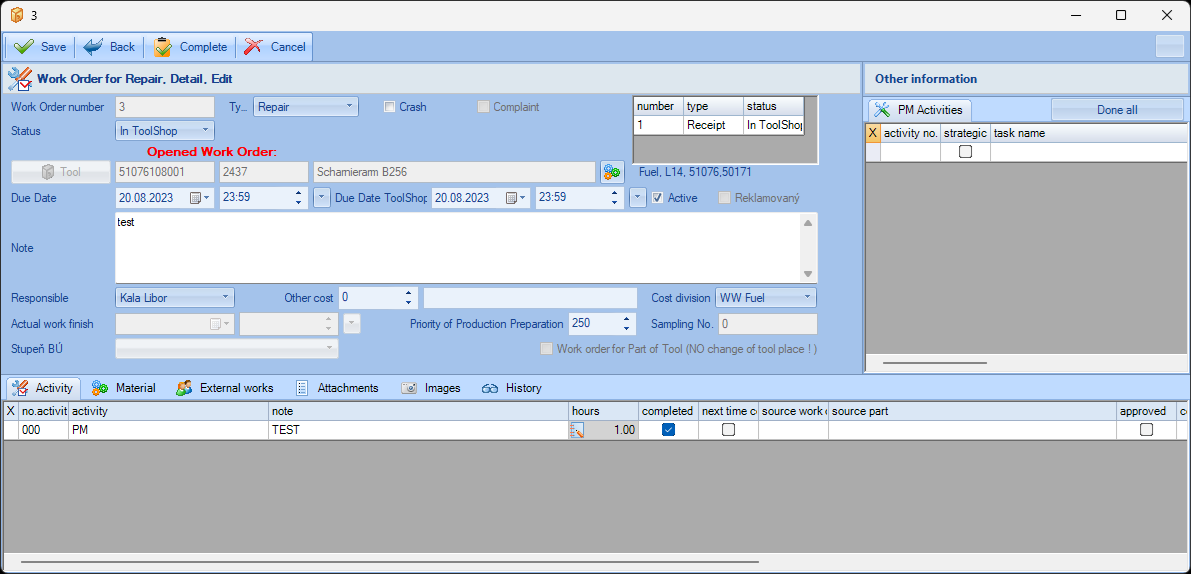

🧰 Work Orders

Centralized request handling for tool issues and repairs. When a tool fails, maintenance or production staff can create a work order directly in the system — no emails or manual coordination needed.

- 📝 Requests created by production or maintenance

- 📥 Unified queue for toolshop personnel

- 🔍 Clear visibility of issues and priorities

- 📎 Attachments and notes for problem description

- 👷 Assignment and progress tracking

- 🗂️ Full history and traceability

🏗️ Tool Warehousing

Manage incoming and outgoing tool movements between production and external storage locations. Track availability, storage status, and logistics without manual spreadsheets.

- 📦 Tool receiving and dispatch handling

- 🚚 Transfers to and from external warehouses

- 📍 Storage location tracking

- 🗂️ Movement history and traceability