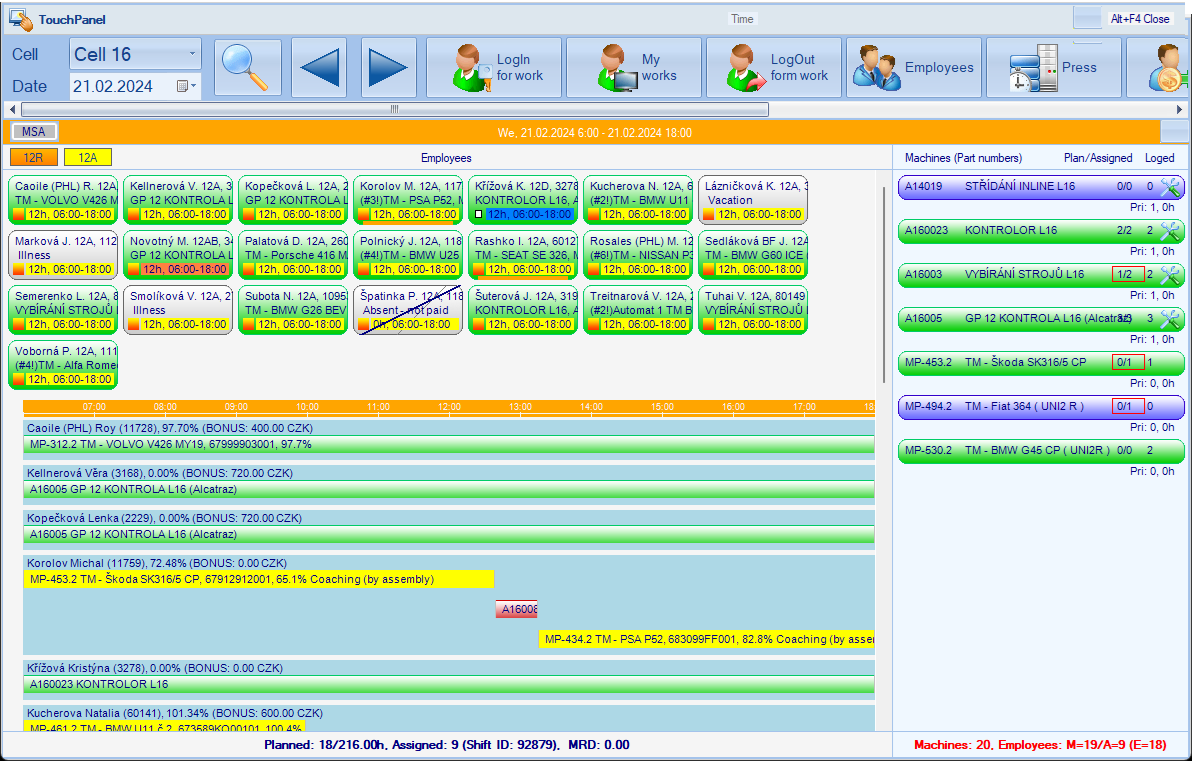

🧭 Shift TouchPanel

A centralized touchscreen interface that gives operators immediate guidance at the beginning of their shift. Positioned at the line entrance or common access point, it provides clear instructions on machine assignments and production tasks, ensuring employees know exactly where to go and what to produce from the first moment on site.

- 🧭 Instant machine and job assignment overview

- 📍 Clear first point of contact at shift start

- ⚡ Reduced confusion and onboarding time for operators

- 📡 Real-time production instructions and priorities

- 🔄 Supports dynamic reassignment based on shopfloor status

- 🤝 Improves shift coordination and operational transparency

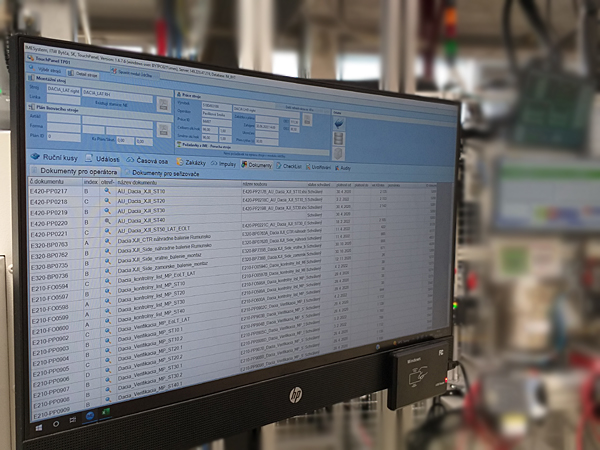

📱 Shared Machine TouchPanel

A production-focused interface mounted directly at a machine or shared across a machine group, depending on customer preference. It acts as a compact MES workstation for operators, providing immediate access to production data, documentation, and quality tools needed for day-to-day execution on the shopfloor.

- 📄 Access controlled documentation directly at the machine

- 🗑️ Manual scrap reporting with structured classification

- 📋 Full visibility of scheduled jobs and work instructions

- 🧩 BOM and material reference available on demand

- ⏱️ Interactive timeline and production context overview

- 🛠️ Support for layered audits, training, and in-process checks

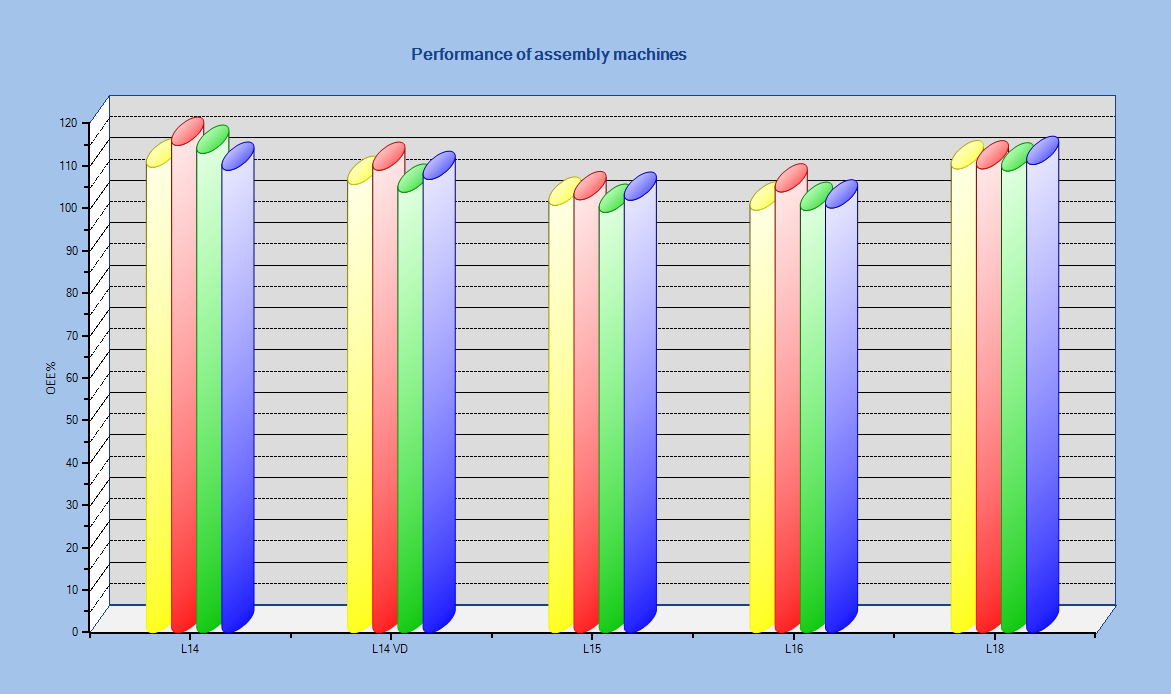

📊 Info Panel

A web-based visualization dashboard designed for large displays in the production hall. Running on Smart TVs or industrial screens, it provides real-time visibility into machine and operator performance, using clear visual cues and color-coded indicators to highlight priorities, issues, and achievements across the shopfloor.

- 📈 Live performance overview of machines and operators

- 🎨 Color-coded status highlighting for instant situation awareness

- 🧮 Flexible aggregation by line, shift, plant, or time window

- 🛠️ Tool repair and maintenance request visibility

- ⚠️ Machine failure and incident monitoring

- 🌐 Runs as a lightweight web app on standard displays

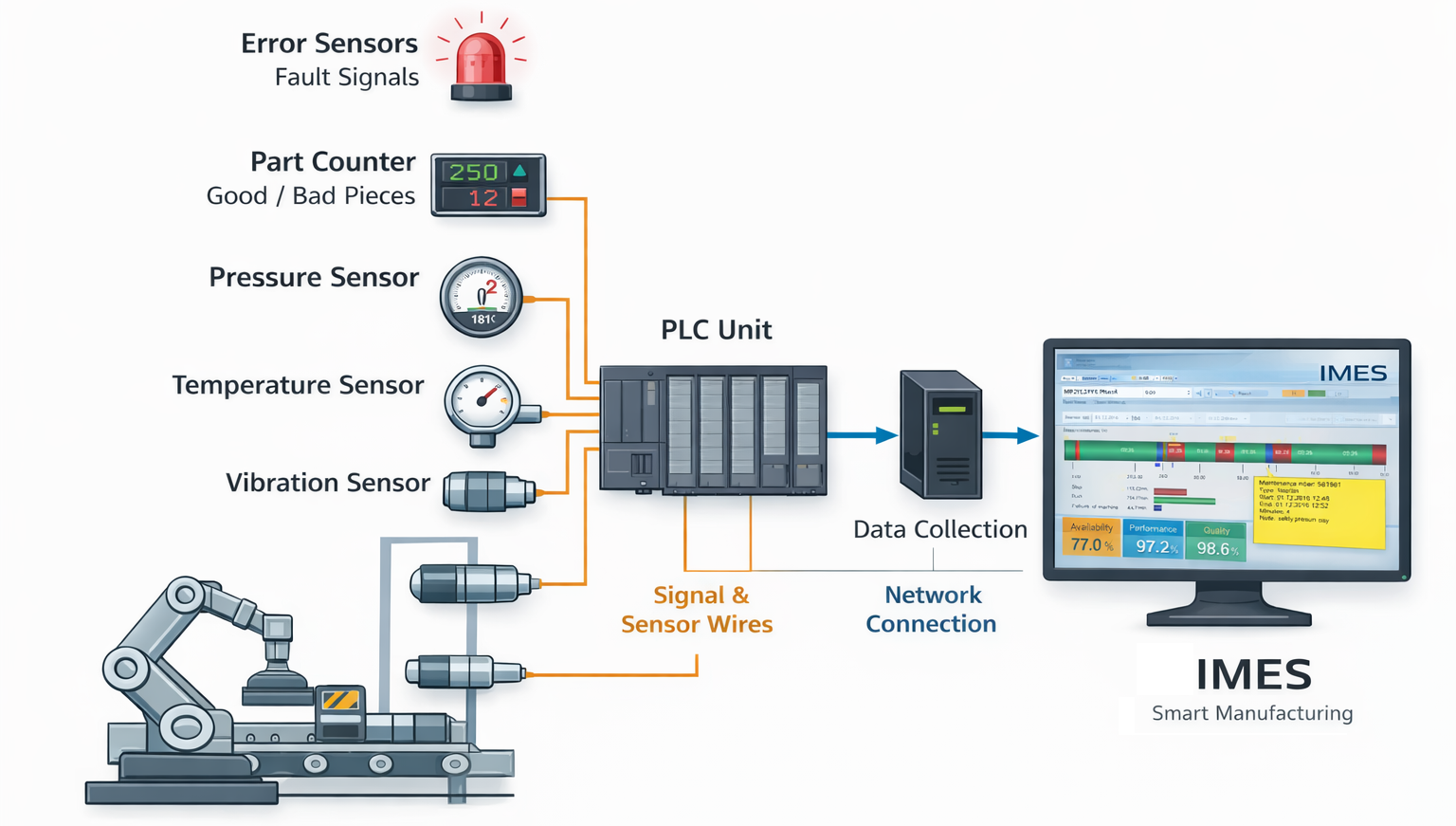

⚙️ PLC Integration

Direct connection to industrial machines via PLC communication enables automatic collection of production signals and process parameters without manual input.

- ✔️ Monitoring of good pieces, scrap, and machine states

- 📡 Reading process parameters (pressure, temperature, vibration, etc.)

- 🏭 Scalable architecture for deployment across large production halls

- ⚡ Reliable real-time data transfer

- 📊 Automatic KPI and OEE calculations

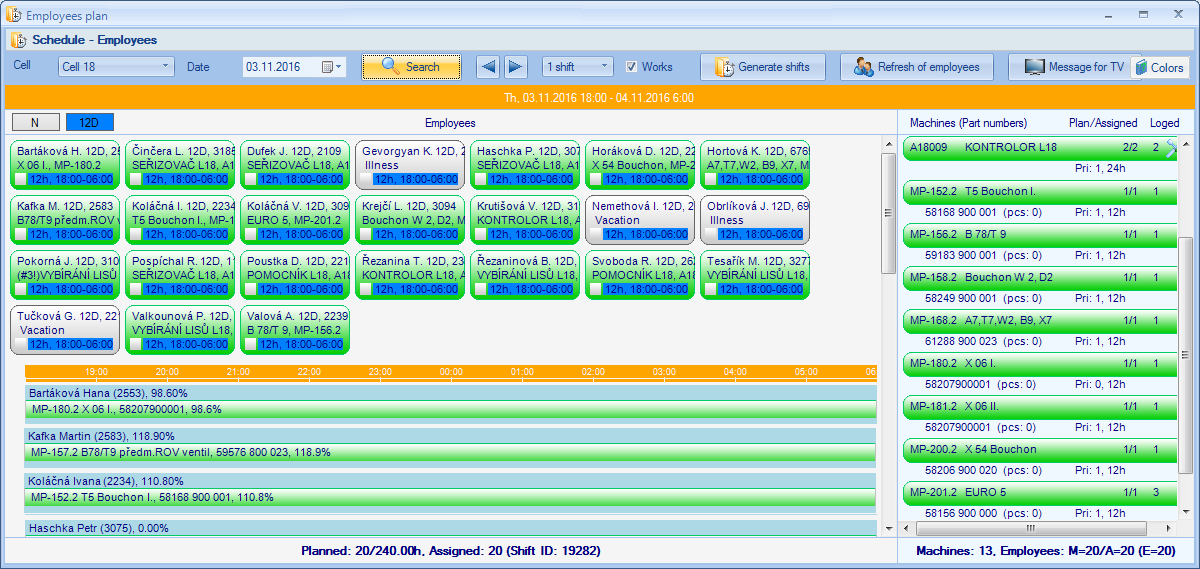

📅 Shift Planning

Plan shifts, assign operators, and connect production orders in one place. Orders imported from ERP are distributed based on capacity, ensuring employees always have clear and relevant work assignments.

- 🗓️ Flexible shift structure and planning

- 🔗 Seamless order import from ERP

- 👷 Operator assignment to specific jobs

- 🔄 Automatic offering of alternative work

- 📊 Capacity-driven dynamic planning

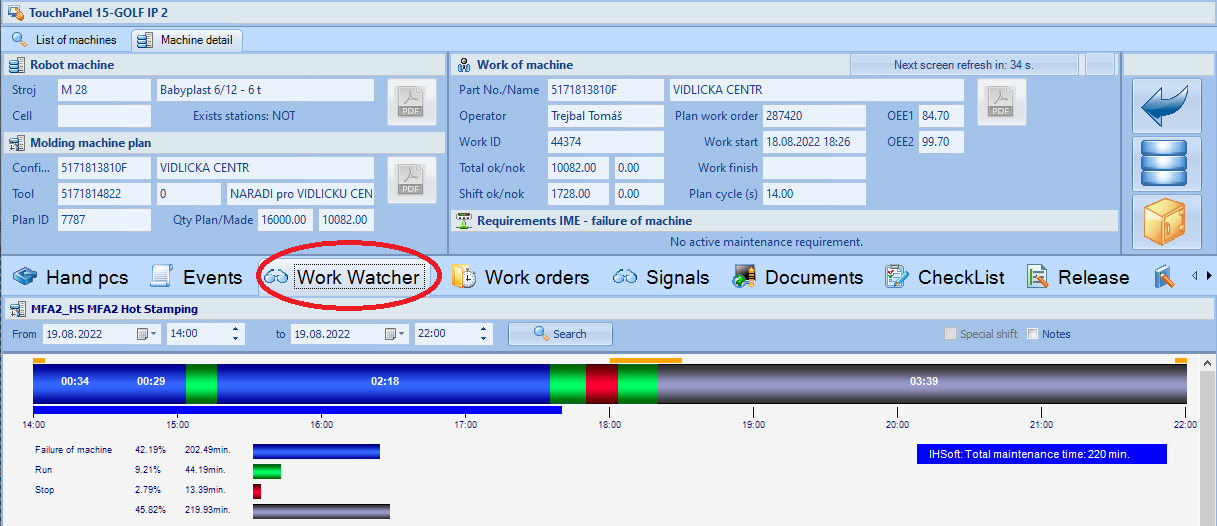

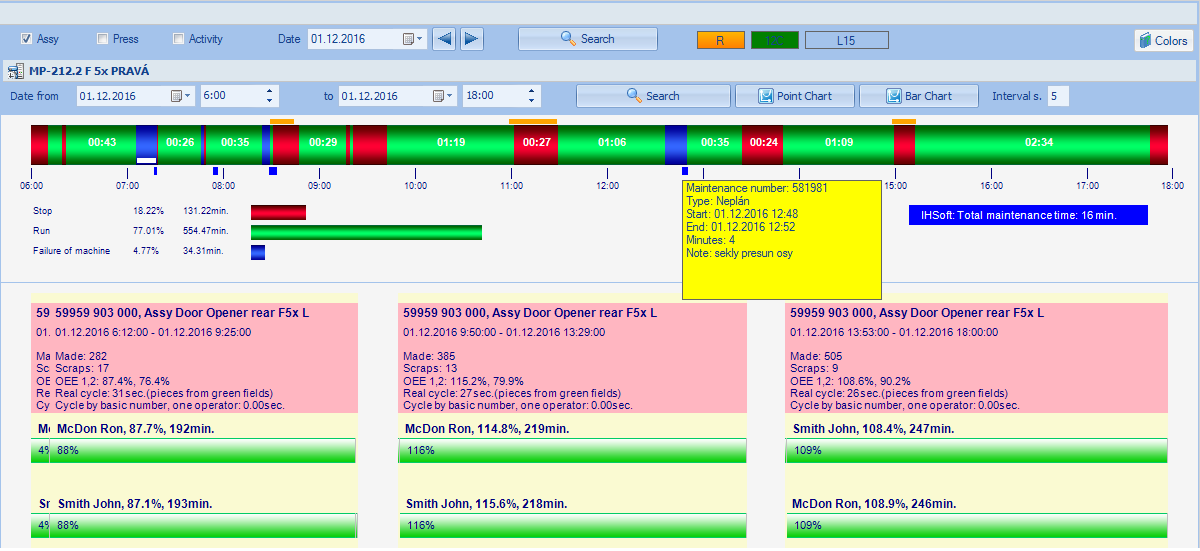

👁️ Work Watcher

Real-time visibility into machine and operator activity. Track production progress, downtime, scrap, and performance on a clear timeline — with the option to enter manual data when automation is not available.

- 🟢 Live employee login and activity status

- 📊 Continuous OEE recalculation

- 📦 Tracking of produced and defective pieces

- ⚙️ Machine state history (Run / Stop / Failure)

- ✏️ Manual event and data entry support

- 📋 Absence and attendance records

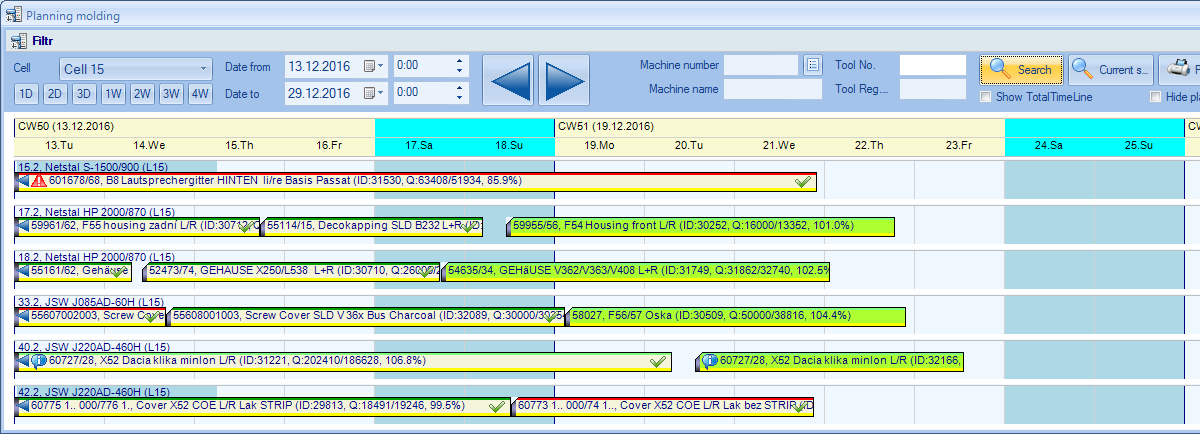

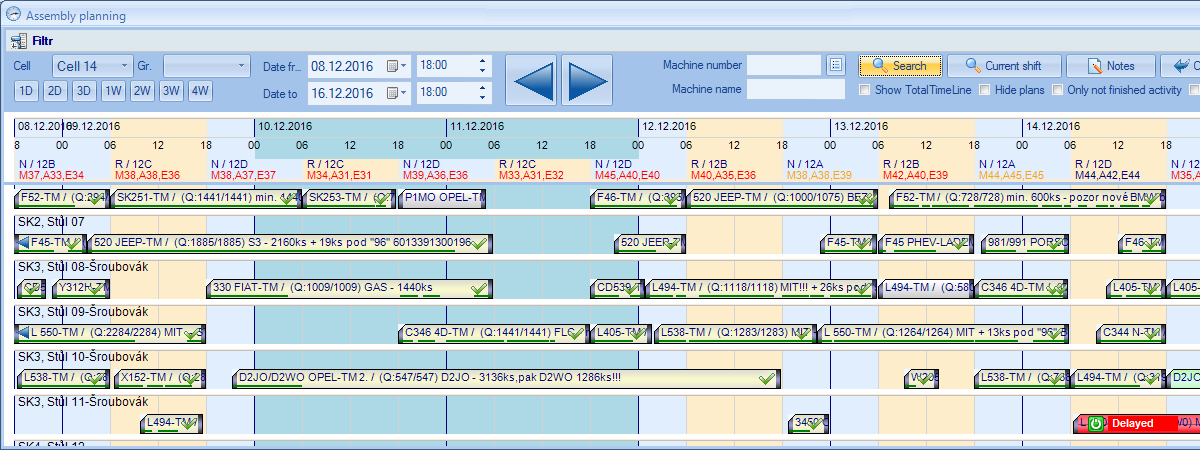

🧠 Production Planning

Advanced planning tools for press shops and assembly lines. Orders imported from ERP are automatically scheduled while planners retain full control to adjust priorities, capacities, and constraints in real time.

- 🤖 Automatic planning from ERP orders

- 🏭 Dedicated workflows for pressing and assembly

- 📊 Capacity-aware scheduling

- 🔄 Drag & drop manual adjustments

- ⚡ Instant recalculation after changes

- 👁️ Clear visual overview of workload and bottlenecks