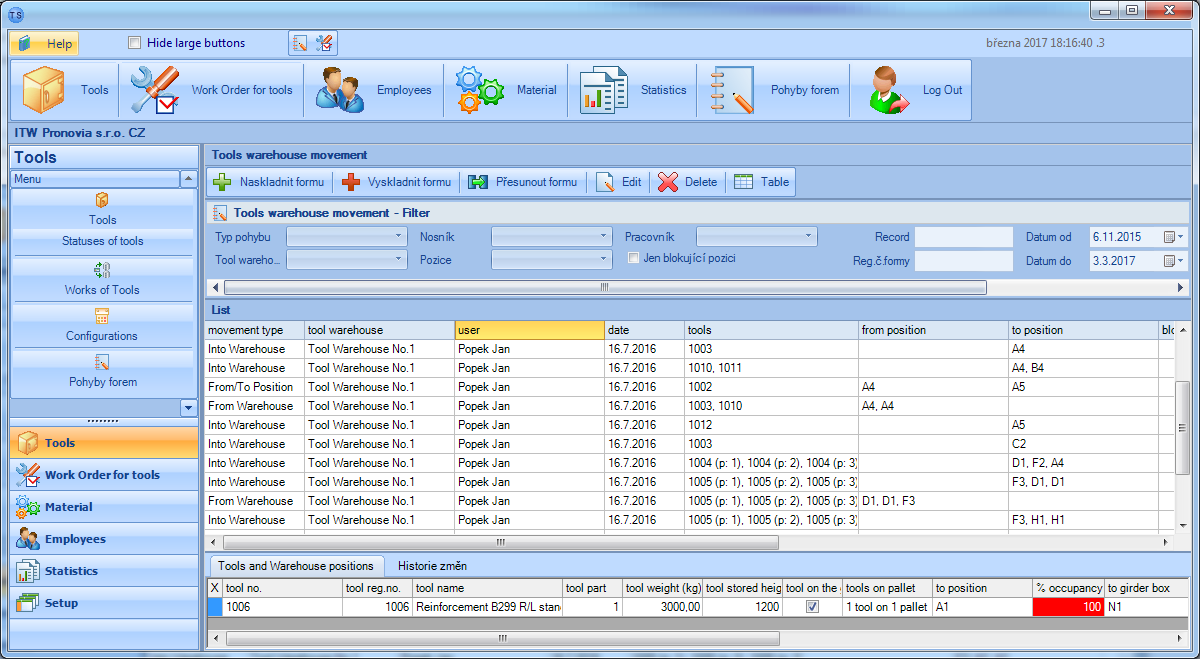

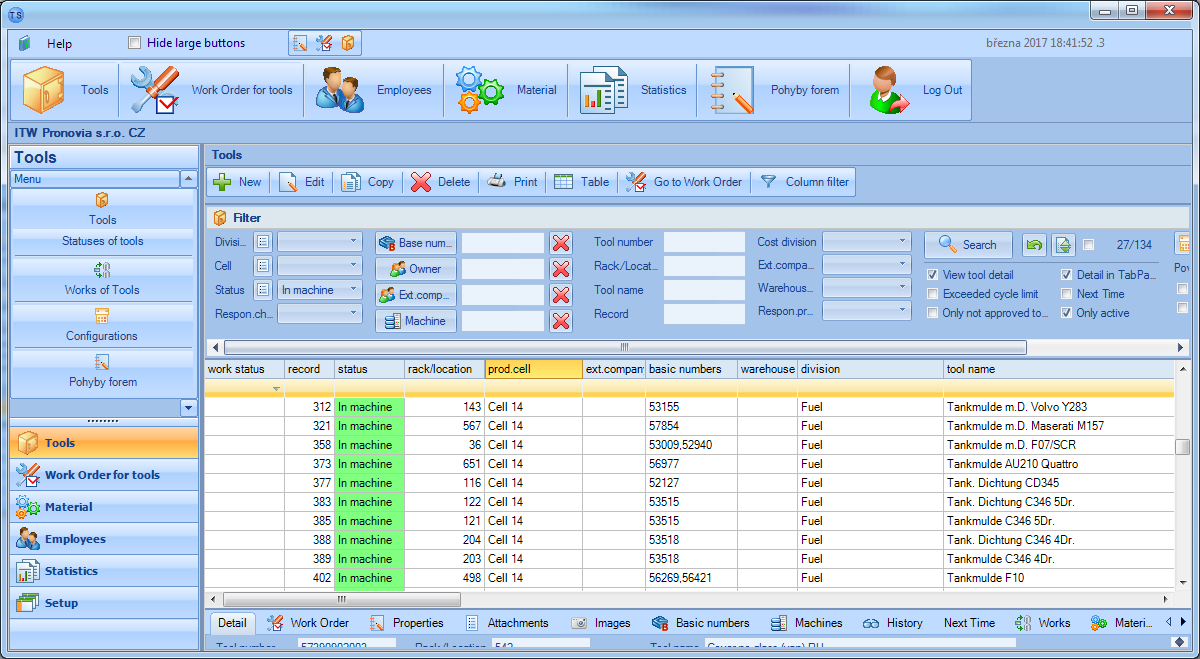

ToolShop is based on two main functions. Which are “Movements of tools” and “Work Orders”. Subsystem “Movements of tools” is used to locate any tool (tool=manufacture form) in your own factory regarding by titles in machine, crashed form or tool is in warehouse . Also in subsystem “Movements of tools” we can find function for arranging tools in warehouse which saves your room in warehouse for tools. Second and momentally last subsystem in ToolShop carries name “Work Order for tools”. “Work Order for tools” is basically informs toolmakers about broken or in case of regular maintenance it generates requested maintenance from our production module IMESystem.

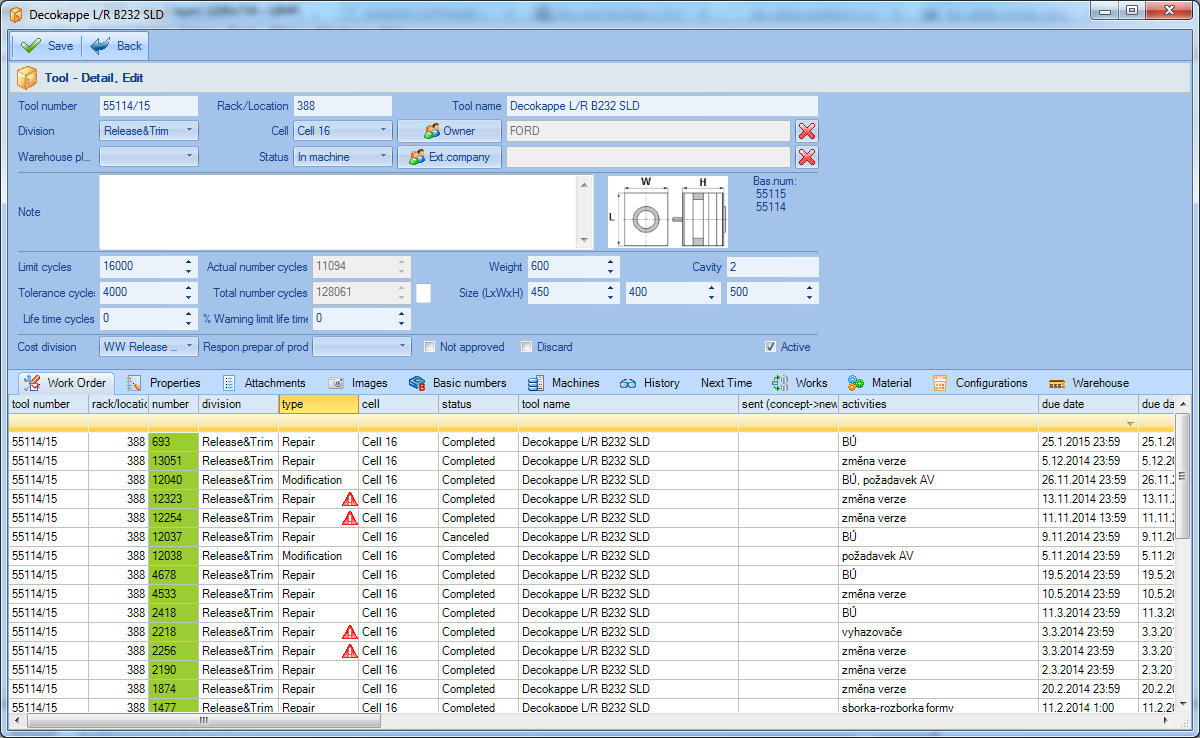

In this form we are able to create new tool or basically edit old one (add new photos, informations, etc..). For each tool we can assign this information:

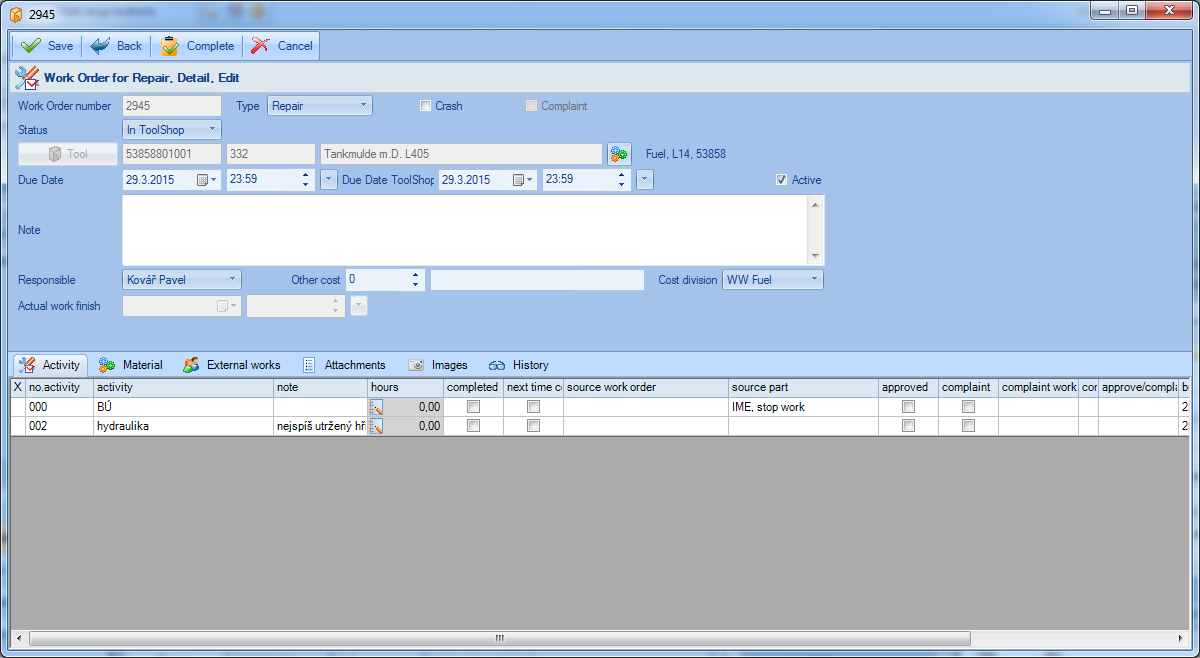

Now little bit more about subsystem “Work Orders”. Our management tried to combine all types of maintenances of tools to one window where every type of maintenance is separated by color which is easily recognizable for toolmakers and maintenance guys.